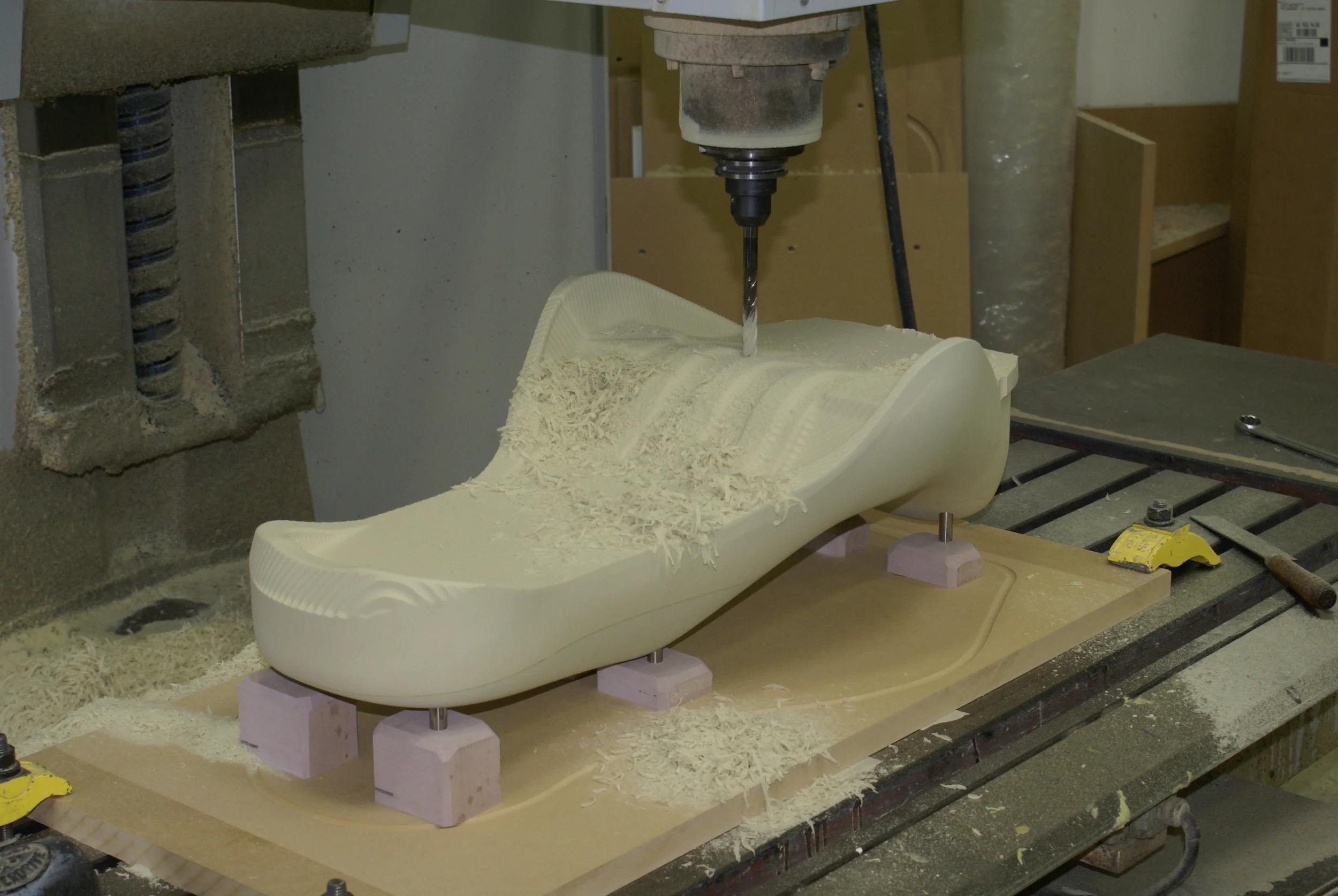

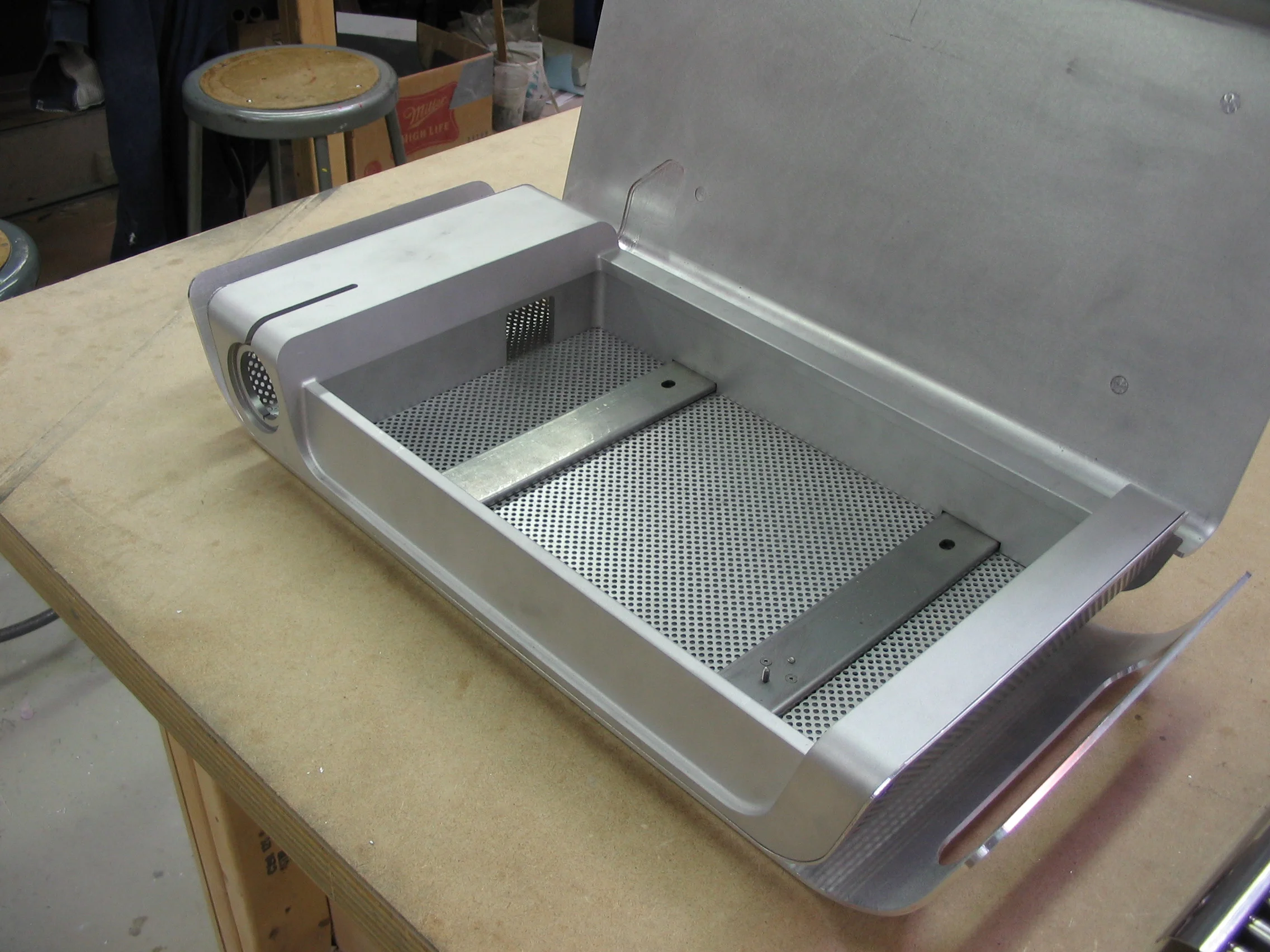

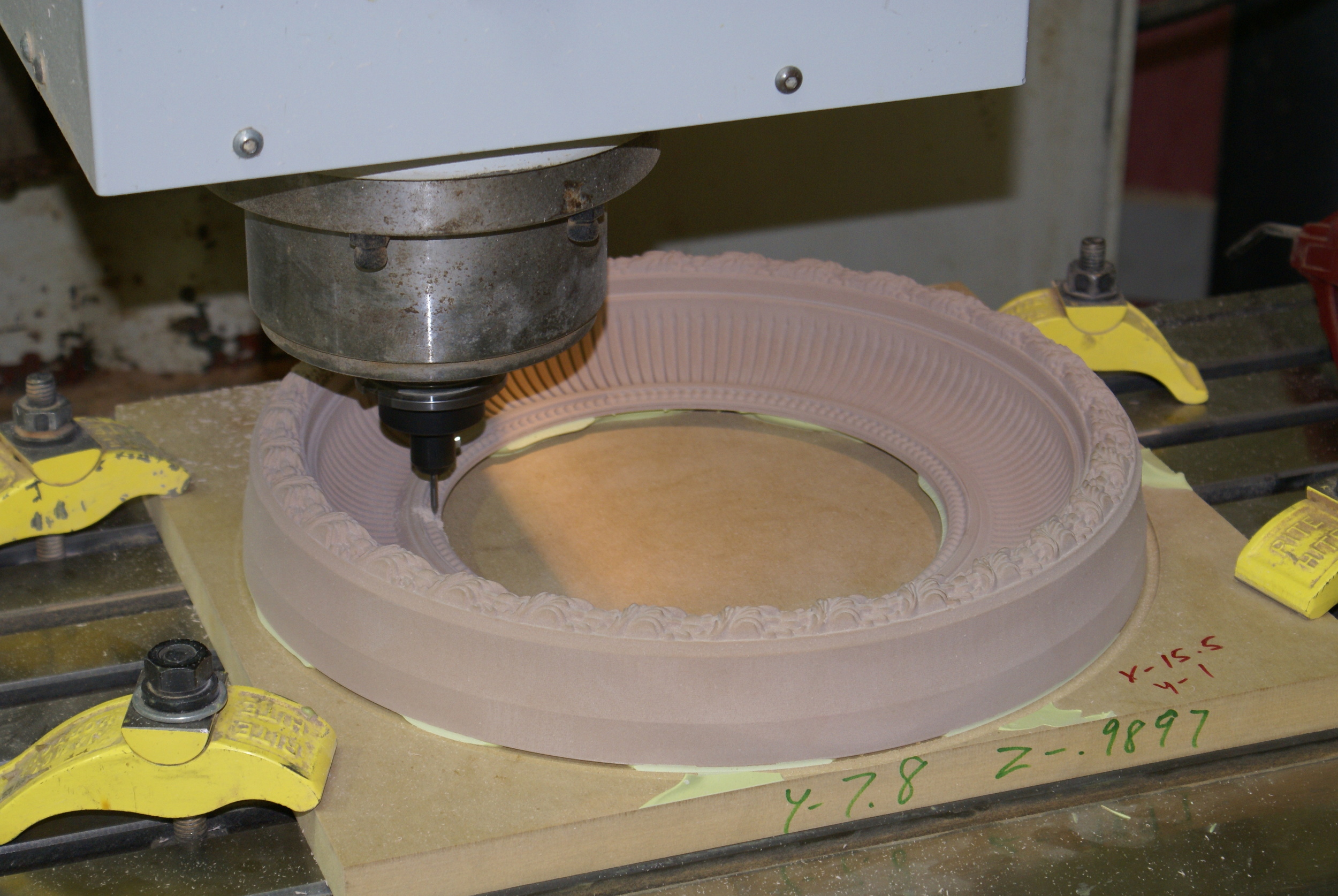

PRESENTATION MODELS

Prototyping methods may vary due to cost or timing requirements but the appearance and feel of a presentation prototype will be as close to actual production that is required by the individual customer. Surface and paint specifications can be exacting as well as detailing and decorating.

Collecting valuable market feedback is a critical step in the development process.

Applications:

Photography

Focus groups

Design reviews

Aid in developing sales literature

Sales tool